If you’re looking for a specially designed part with very unique properties, custom RIM molded products solve many manufacturing needs world-wide. This niche industry that we’re proud to be a part of creates products and parts that many manufacturers rely on and use. However, not many in the United States actually manufacture these products. In fact, DiMax Corporation is one of only a couple companies that specialize in this process and make a large portion of RIM Molded products right here in the USA, and help other businesses avoid costly outsourcing overseas. If you’re looking for a trusted company to manufacture your RIM products, we’re right here in Winsted, Minnesota.

The Clear Benefits of Custom RIM Molded Products

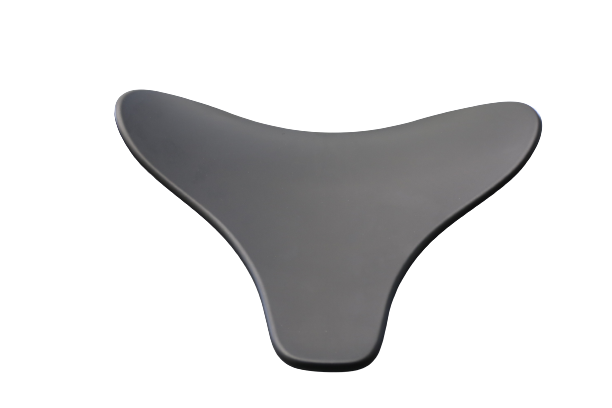

Custom RIM molded products are those that are manufactured to very unique specifications, usually to be used as a part within a larger, more complex manufactured product. At DiMax we work with clients and their engineers who provide us their designs and we take care of the RIM parts. Our team works extensively with physical fitness and medical industries. We use the RIM molding process to manufacture seats for exercise equipment, as well as back and neck rests for wheel chairs. However, the sky is the limit on how this process can help innovate and improve products in a number of industries including recreational, agricultural, industrial, medical, and more.

RIM, or Reaction Injection Molding, is a process that uses urethane foam that is sprayed or poured into a mold. A thermal reaction heats the material up until it fills the mold and cures within about 6 minutes. This process creates a skin that looks solid, but has foam inside that can range from soft to very firm. The benefits of RIM molded products include durability, impact resistance, shock absorption, and lighter weight. Custom RIM molded products can also be made in virtually any shape or size, and the process is extremely versatile, making it ideal for creating custom parts and applications.

Tell us about your project, and we will share what’s possible! If you have questions, give us a call today at (320) 485-3232! You can also request a prototype or get a quote.