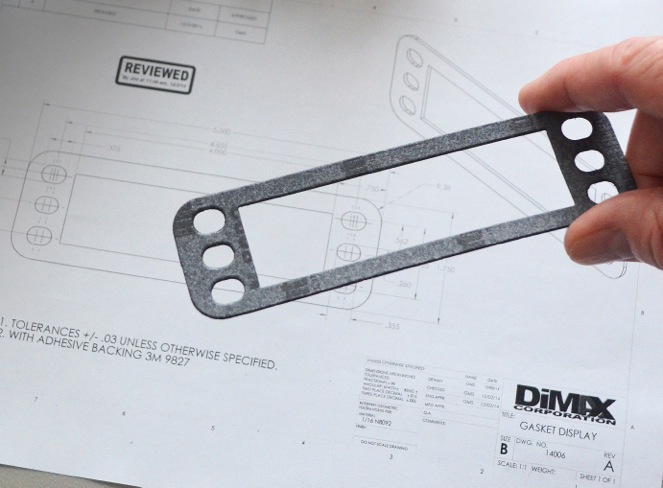

Creating Unique Die Cut Parts to Help Complete Your Project

We know how important consistent quality and delivery is to your products. Our high precision equipment stamps out uniform parts – from simple designs to complex pieces with tight tolerances.

Die Cutting Capabilities

We have die cutting capabilities to match every possible need. We can cut parts from a large variety of non-metallic material, giving you lots of options. Some of our die cutting services and material stamping capabilities include flat bed, multi-layer cutting, kiss cutting, lamination, die cutting, and more.

DiMax is an engineer preferred choice for mid – high volume production.

Why Choose DiMax?

- Certified ISO-9001:2015

- Extreme precision when achieving “perfection” is required

- 30+ years die cutting & engineered materials experience

- One-stop-shop for a wide variety materials we convert

- Flexible quantities when medium to large volumes are needed

- Experience accommodating companies manufacturing everyday needed products

There are several types of die cutting processes that we offer at DiMax, including:

- Flat Bed Cutting

- Multi-Layer Cutting

- Kiss Cutting

- Laser Cutting

- Lamination

Frequently Asked Questions

If you cannot find an answer to your question below, please give us a call at (320) 485-3232 or fill out our contact form.

How long until I receive a quote?

We strive for a quick turn-around time on quotes. About 90% of quote requests received are complete that same day. To request a quote, give us a call at (320) 485-3232 or fill out the form below.

What is the product turn-around time?

Products are completed in 2-3 weeks.

Do you convert 3M products?

Yes! We are a select converter for 3M. We also specialize in 3M Single or Double-Sided VHB Tape.

What types of materials do you convert?

We convert a wide variety of non-metallic materials to fit your needs from die cut plastic, foam, rubber, fiber, felt, thermal insulation, and more! View our list of materials below.

Can you help me find the right material?

Of course! With over 30 years of experience in the die cutting industry, we can help you define what type of materials are ideal for your application. Then, we’ll provide sample parts until it is just right. We work with all the material manufacturers and can help you find the best material(s) for your application.

What are the die cutting tolerances?

Our die cutting tolerances are typically +-.015’’.

How many parts will you convert?

We are a preferred choice for mid-volume production of OEM components. We’re capable of producing one to millions of parts. We most commonly manufacture anywhere from 100 – 2,500 pieces.

Can I get a prototype?

Yes! We have a machine that can make samples without even having to buy a tool. You can request a prototype by giving us a call at (320) 485-3232 or by filling out the form below.

Non-Metallic Materials We Convert

We can help you define what type of die cut materials are ideal for your application, and then provide sample parts until it is just right.

Rubber

- Buna-N

- ECH

- EPDM

- FDA Rubber

- Hypalon

- Latex

- Neoprene

- Polyurethane

- Pure Gum

- SBR

- Santoprene

- Silicone

- TPR Rubber

- Nitrile Rubber

- Recycled Rubber

- Reinforced Rubber

- Vinyl

- Viton

Plastic

- ABS

- Acetal

- Delrin

- Epoxy

- Laminate

- HDPE

- Kapton

- LDPE

- Lexan

- Nylon

- Polycarbonate

- Polyethylene

- Polypropylene

- PVC

- Seaboard

- Teflon®

- UHMW

- Vinyl

Foam

- Buna-N

- Crosslink

- Polyethylene

- ECH

- EPDM

- Laminated Foam

- Neoprene

- PVC

- SBR

- Sponge Blend

- Silicone

- Urethane (Poron)

- EVA

Insulation

- Electrical

- EMI/RFI Shielding

- Thermal Materials

- Sound Materials

- Vibration Materials

- Nomex

- Formex

- Fishpaper

- Kapton

Fiber

- Pure Cork

- Cork Rubber Blend

- Cellulose

- Compressed

- Reinforced

- Graphite

- Vellumoid

- Nomex

- Fishpaper

Adhesives (PSA)

- Acrylic

- Conductive

- Velcro

- Rubber

- Silicone

- Safetywalk®

- VHB

Films

- Acrylic

- Copper

- Formex®

- Lexan

- Polycarbonate

- Normex

- Polyester (Mylar®)

- Polycarbonate

- Valox

Felt

- Wool

- Synthetic

Working Together for the Best Final Product

Our experience has taught us that the best outcomes result from working together in the design of the product. When we can collaborate during the design phase and provide input on specifications such as the material, size and location of features, and tolerances, it helps to lower the part cost and improve reliability.

Our Certifications

Our commitment to you is a set of resources that go well beyond the norm of our industry in order to compete in rapidly changing, technology driven, often worldwide markets.

Request a Quote or Prototype

DiMax is ready to turn your design into reality. Get started by requesting a free quote on your next die cutting project with the form below or give us a call at 320-485-3232. We will get in touch with you promptly.