Urethane RIM Foam Molding Suitable for a Wide Variety of Applications

Our reaction injection foam molding is suitable for many applications including industrial, medical, and recreational products. Tooling cost for RIM foam molding is substantially lower than plastic injection molding, and our lead times are quick!

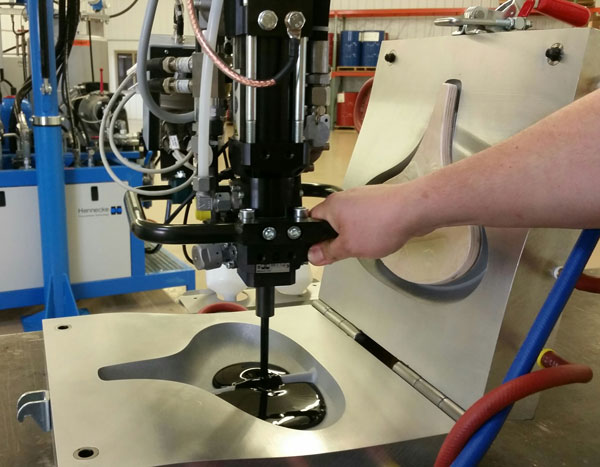

RIM Foam Molding Capabilities

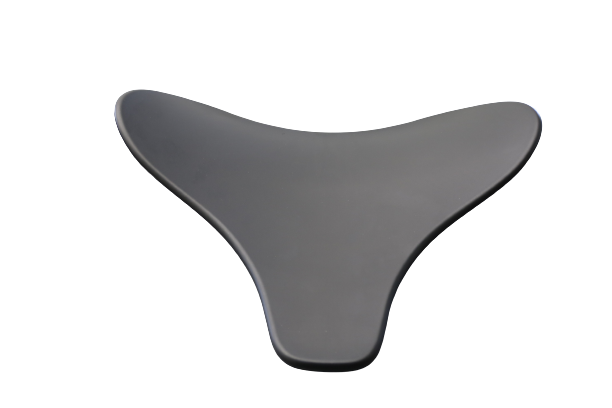

Parts made from foam molding are ideal for any application that requires a tough urethane skin with a memory foam inside that can absorb shock, vibration, or compression. The RIM process allows us to produce various shapes and densities that are tear-resistant with a durable, high quality, & easy-to-clean surface.

We can create bigger parts in any shape with RIM molding – tell us about your project and we will share what’s possible!

DiMax is an engineer preferred choice for mid – high volume production.

RIM Molding Features & Benefits

- Urethane skin with a memory foam inside

- Absorb shock, vibration, or compression

- Tear resistant foam for tough uses

- Easy cleaning with the Integral foam self skinning surface

- Soft or hard foam material options

- Open cell foam provides cushion support

- Over-molded inserts (metal, plastic, or wood) can help your design potential

- Fire rated/Cal 117 for safety

- Popular option for durable medical equipment products; does not irritate skin

Engineer Preferred

DiMax’s RIM foam molding formula is durable. The foam material is designed for applications that require high tensile strength, durability, and an attractive finish.

Working Together for the Best Final Product

Our experience has taught us that the best outcomes result from working together in the design of the product. When we can collaborate during the design phase and provide input on specifications such as the material, size and location of features, and tolerances, as it helps to lower the part cost and improve reliability.

Our Certifications

Our commitment to you is a set of resources that go well beyond the norm of our industry in order to compete in rapidly changing, technology driven, often worldwide markets.

Request a Quote or Prototype

DiMax is ready to turn your design into reality. Get started by requesting a free quote on your next RIM project with the form below or give us a call at 320-485-3232. We will get in touch with you promptly.